THE COMPANY

IN FIGURES

531

Employees1

2

Facilities: Olbia and Vila do Conde

5.428.000

Households that consume products bearing the ASDOMAR2 brand name

7,9%

Marketshare of ASDOMARin the tuna market 3

2a

Brand in value of the tuna market in Italy

14,9%

Market share of Generale Conserve in the tuna market 4

approx 300

The key players in trade withwhich the company has commercial relationships

APPROX

152 MILLION euro in turnover5

67,6 %

ASDOMAR brand

31,6%

Private labels0,1%

Other

0,7%

Fishmeal

- Figure expressed in annual work units (AWU). Also includes 21 employees from the headquarters in Genoa, employees on fixed-term contracts, seasonal employees and staff on temporary contracts, working primarily during peak production periods at the Group’s facilities.

- Turnover gross of price adjustments for discounts, premiums and commercial services rendered by retailers.

- Data source: Circana TOTAL ITALY I+S+LS YEAR 2023. Tuna in oil Market < 300g Supermarket + Superstore + Self-Service channel – ASDOMAR brand.

- Data source: Circana TOTAL ITALY I+S+LS YEAR 2023. Tuna in oil market <300g Supermarket + Superstore + Self-Service channel – Includes the ASDOMAR brand and Private Label products.

- Data source: GFK – Annual Progress Report DEC23.

THE HEART OF OUR IDENTITY:

THE PEOPLE

I sent a simple CV and it was the start of a love affair: this is where I grew up, both professionally and personally

I sent a simple CV and it was the start of a love affair: this is where I grew up, both professionally and personally

Sara Cleaner

Sawyers, cooks, cleaners, laboratory technicians and many other experts and craftspeople. Thanks to their invaluable contribution, Generale Conserve combines the ancient art of fish processing and the innovation of new technologies, with a view to continuously evolving towards ever-increasing quality and product focus.

La storia di

Alessandro, responsabile della linea vaso vetro

THE PHASES OF THE

PRODUCTION PROCESS

1

RECEIPT AND STORAGE OF RAW MATERIALS

Read more

Raw materials are unloaded in special areas of the plant, weighed and conveyed to the different storage areas with a specific batch, identified to ensure internal traceability. Sample checks are performed on each batch for food safety.

2

CUTTING AND PREPARATION FOR COOKING

Read more

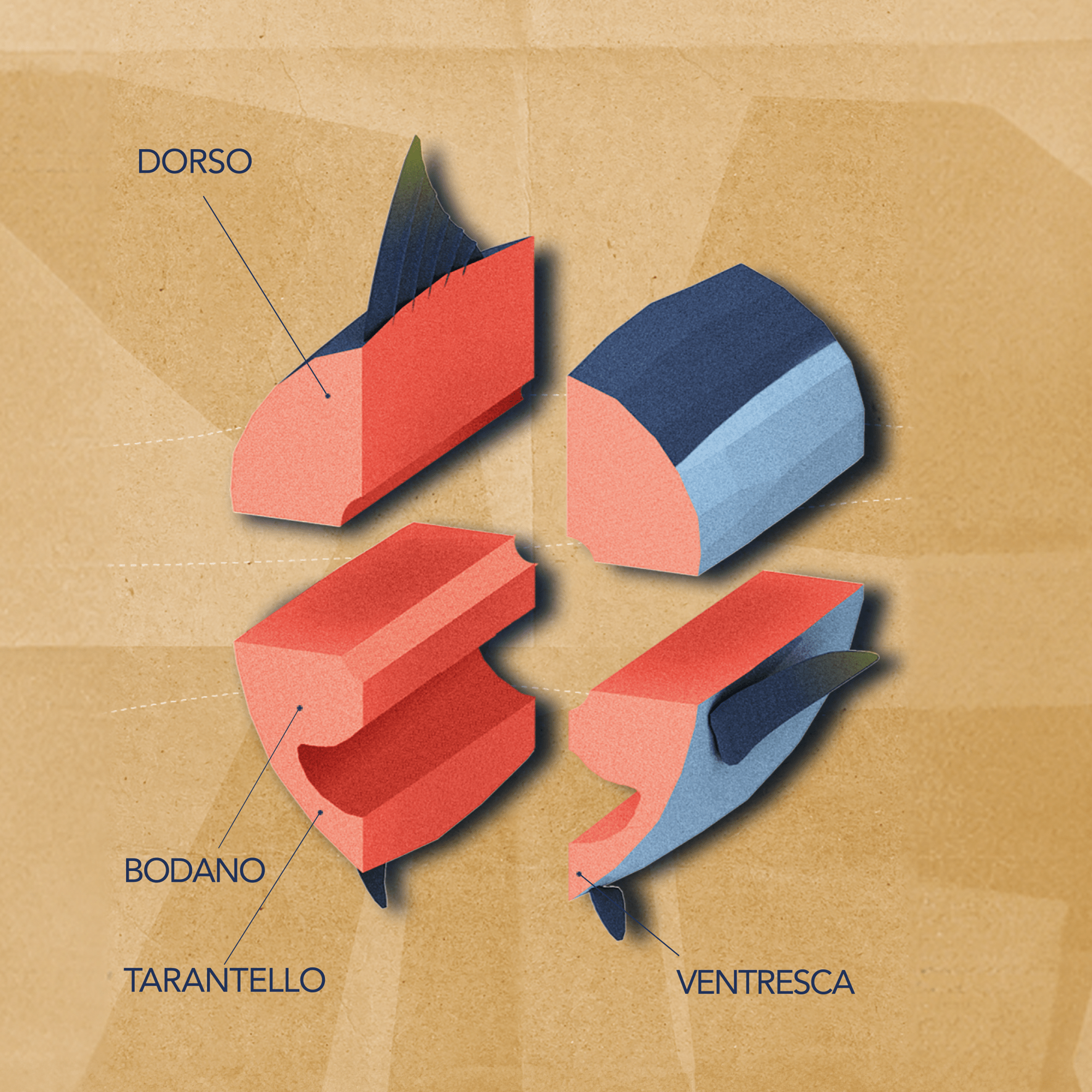

The tuna is taken from the cold rooms and conveyed to the dedicated area for the various cuts (head/tail, loins, back, belly).

3

Cooking

Read more

Cooking takes place in steam ovens and is monitored electronically through probes for controlling the temperature that send the data to a control panel. There is a cooling phase at the end of cooking.

4

Conditioning

Read more

Conditioning begins with an atomising system and is then completed in the Chill Room (an air-conditioned room between 0 and 5 degrees), where the tuna is kept overnight in the dark to firm up and remain whole and compact.

3

Cooking

Read more

Cooking takes place in steam ovens and is monitored electronically through probes for controlling the temperature that send the data to a control panel. There is a cooling phase at the end of cooking.

4

Conditioning

Read more

Conditioning begins with an atomising system and is then completed in the Chill Room (an air-conditioned room between 0 and 5 degrees), where the tuna is kept overnight in the dark to firm up and remain whole and compact.

5

Cleaning

Read more

Each cleaning line is composed of two stations, one where the first cleaning phase takes place (removal of skins, underskins, bones, red meat, etc.) linked via a conveyor belt to the second phase where trimming and quality grading takes place. For each cleaning line, there is a dual system of differentiated waste recovery.

6

CANNING and potting

Read more

The facility contains separate sectors for packing the various products into cans or jars. For example, in Olbia, where the greatest variety of packaging and references may be found, the tuna is sorted for packaging in the following materials: tinplate cans, glass jars, cans for mixed products, tubes for pâté, etc.

5

Cleaning

Read more

Each cleaning line is composed of two stations, one where the first cleaning phase takes place (removal of skins, underskins, bones, red meat, etc.) linked via a conveyor belt to the second phase where trimming and quality grading takes place. For each cleaning line, there is a dual system of differentiated waste recovery.

6

CANNING and potting

Read more

The facility contains separate sectors for packing the various products into cans or jars. For example, in Olbia, where the greatest variety of packaging and references may be found, the tuna is sorted for packaging in the following materials: tinplate cans, glass jars, cans for mixed products, tubes for pâté, etc.

7

Sterilisation

Read more

After the dosage of preserving liquids and closure, the next phase is sterilisation. This is the zone that comes after packing, where products are sterilised in steam autoclaves (tinplate cans) or water autoclaves (glass jars).

8

Packaging

Read more

Once sterilised, the products are washed, dried, labelled and packaged.

7

Sterilisation

Read more

After the dosage of preserving liquids and closure, the next phase is sterilisation. This is the zone that comes after packing, where products are sterilised in steam autoclaves (tinplate cans) or water autoclaves (glass jars).

8

Packaging

Read more

Once sterilised, the products are washed, dried, labelled and packaged.

THE CHOICE OF

LOCATION

RESPECT

FOR THE SEA

As sources of raw materials, the sea and the marine ecosystem are precious resources, which must be defended to ensure the quality and respect of our products. Generale Conserve operates 100% sustainable fishing and bases its actions on the principles of protecting the seas and marine biodiversity.

SUSTAINABLE FISHING

SUSTAINABLE FISHING

ONLY CERTIFIED PRODUCTS

ASDOMAR brand products are Friend of the Sea-certified according to the requirements for sustainable fisheries and social responsibility, carefully monitored by accredited external certification bodies.

DOLPHIN-SAFE

We only source from suppliers who guarantee fish raw material from vessels certified Dolphin-Safe by the Earth Island Institute, in line with the Friend of the Sea system.

NO ENDANGERED SPECIES

We do not purchase bluefin tuna (Thunnus thynnus) or any other endangered species.

OCEANS AND SEAS WITH NON-OVERFISHED STOCKS

We only ask our suppliers for tuna and mackerel from fish stock that has not been over-exploited.

SELECTIVE FISHING METHODS

We only process raw fish material caught according to low-impact and selective fishing methods, i.e. limiting the bycatch of non-fished species. We do not use tuna caught with destructive techniques, longliners or large driftnets.

ONLY REGISTERED VESSELS

We only source fish raw material from fleets and fishing vessels not on the IUU list (illegal fishing vessels) and from vessels identified by their own European health register. We purchase raw material that is not transhipped at sea, except with independent observers on board.

MONITORING

We check that each purchase is compliant with the procedures defined internally and the requirements of our specifications, and we undertake to monitor the traceability of the raw fish material.

ZERO WASTE

TUNA

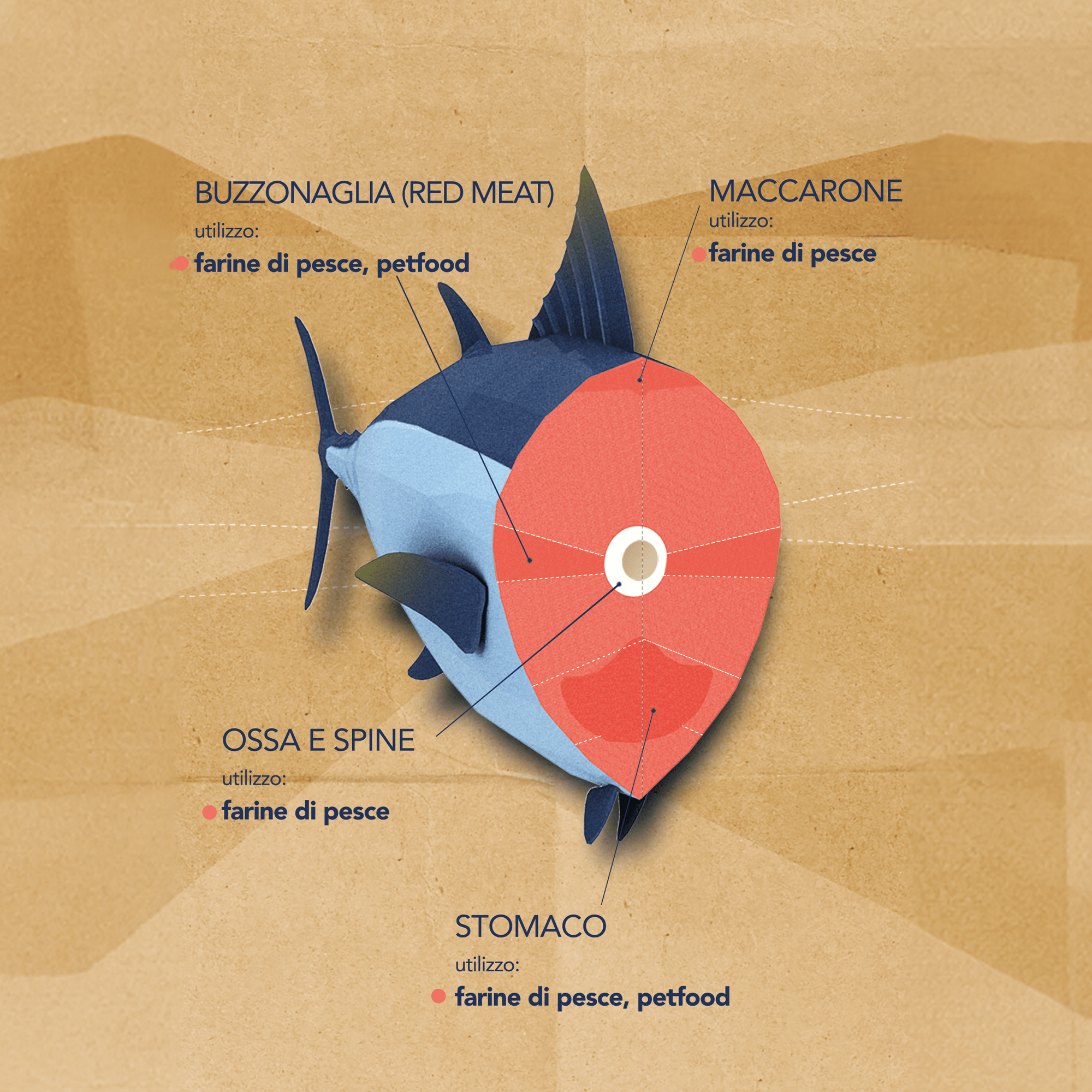

Tuna processing generates over 50% of waste, which is usually sent to landfills.

Generale Conserve reuses 100% of this waste to produce fish meal for animal feed.

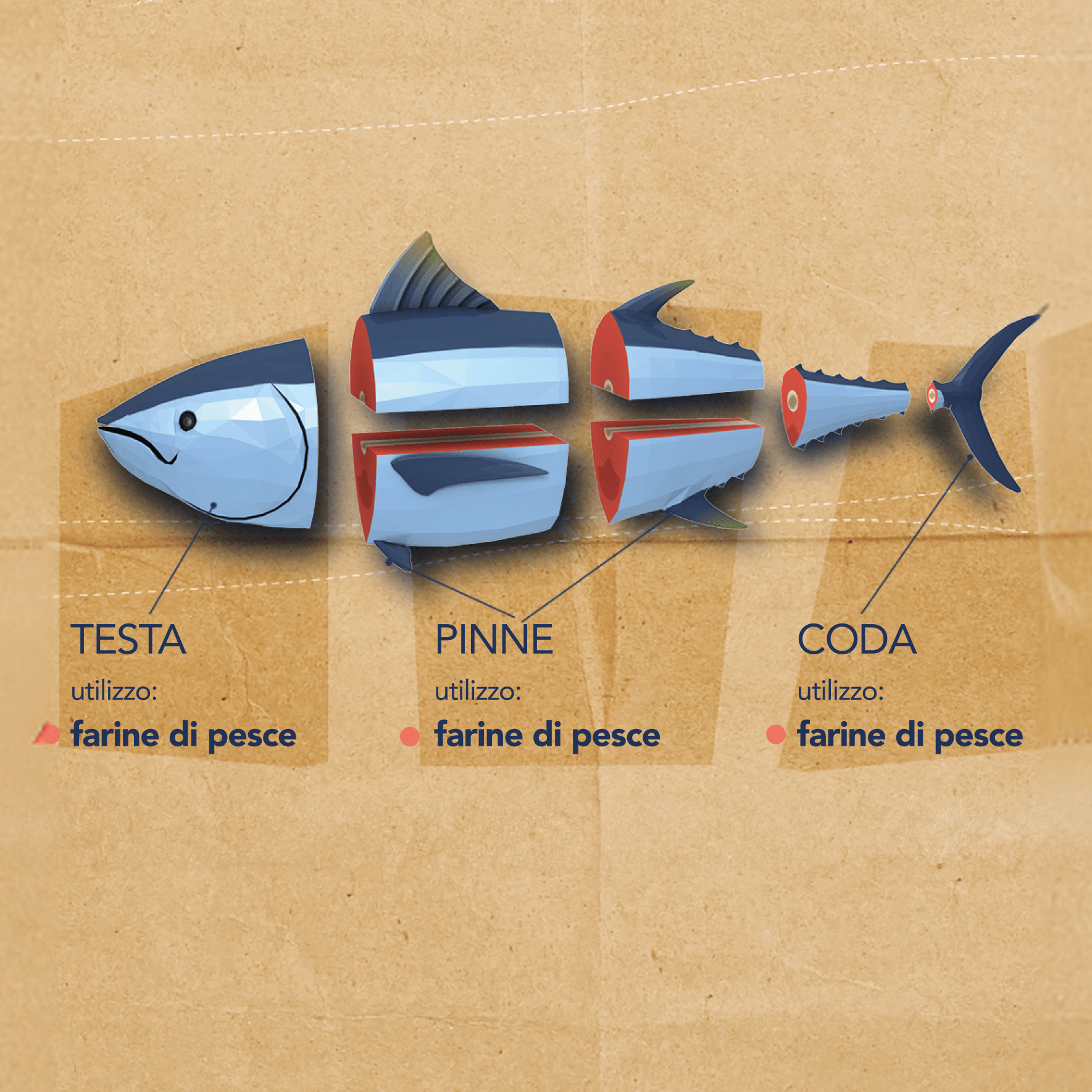

OFF WITH THE HEAD, OFF WITH THE TAIL

Before cooking, the tuna is cut and the outer parts are removed.

THE TUNA IS CLEANED, BUT NOTHING IS DISCARDED

The tuna is cleaned, and the parts intended for other uses are extracted.

My department, the flour plant, is a perfect example of combating waste.

We don’t throw any of the raw material that we use away: we process and reuse every scrap of waste!

My department, the flour plant, is a perfect example of combating waste.

We don’t throw any of the raw material that we use away: we process and reuse every scrap of waste!

Roberto Flour handler

DOWNLOAD HERE

the full PDF of the 2023 Sustainability Report

Our transparency pact with consumers